Dr. Rudy Schlaf's Group_____________________________________________________

Department of Electrical Engineering - University of South Florida

Last Modified Aug 2013

(c) Rudy Schlaf

Webmaster

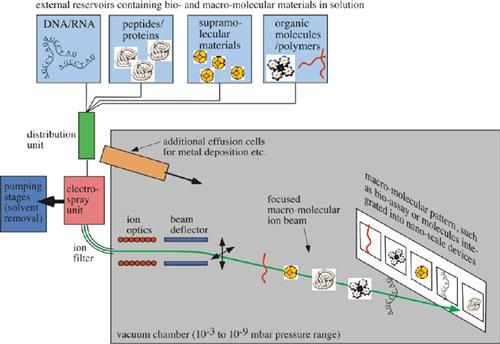

Design and Construction of 3D Patterning Device for Macro-Molecular Materials: There are a wide variety of potential applications for molecular materials of nanometer dimensions arranged through growth and/or patterning into multi-dimensional nanostructures, and significant progress has been made in recent years in the production of these molecular materials. Macro-molecular materials include semiconductor quantum dots, carbon nanotubes, luminescent and semiconducting polymers, and metallic nano dots. Macro-molecular biologically active materials include custom synthesized deoxyribonucleic acid (DNA) oligomers or monoclonal antibodies able to identify pathogenic antigens. These materials are promising for the fabrication of electronic devices, sensors and medical applications. While the synthesis of such molecular materials has in many cases become a routine process, controlled assembly of these materials to form well-defined structures is in many cases quite difficult. However, controlled and directed assembly is crucial for the production of custom tailored devices performing actual tasks like switching or communicating with other components, or bio-assays/sensors with specific pathogen sensitivity. We believe that directed assembly (possibly supported by local self-assembly) represents the key for successful integration of nano-materials into complex electronic devices or sensors. With the currently built device, an electrospray based patterning device operating in vacuum (“MoleculeWriter”), we aim at solving this problem. The schematic design of the MoleculeWriter is shown in Fig.1. The core design components are the electrospray unit, which creates an ionized molecular beam directly from solution inside the vacuum chamber. Through subsequent ion optical elements, where the electrospray beam can be mass filtered, focused and deflected, patterns can be written on a substrate. This allows the preparation of clean 3D structures composed of molecular materials. Future expansion of the MoleculeWriter will include a fluid distribution capability. This will offer the opportunity to prepare well-defined structures composed of a multitude of molecular materials under computer control. |

Fig.1: Preparation of patterned molecular structures with the MoleculeWriter. Molecular materials in solutions are fed through the electrospray (ES) device where solvent and solute are separated and a molecular ion beam is produced. Ion optics and beam deflectors are used to produce a focused beam that can be scanned over a substrate surface, allowing the deposition of 3D patterns to produce structures such as patterned nano-composite layers and/or individually coated regions of a sensor array. This system has recently been completed and demonstrated in our lab. The system is now commercially available. Please, visit www.elionsystems.com for more information. |

|---|