Dr. Rudy Schlaf's Group_____________________________________________________

Department of Electrical Engineering - University of South Florida

Last Modified Aug 2013

(c) Rudy Schlaf

Webmaster

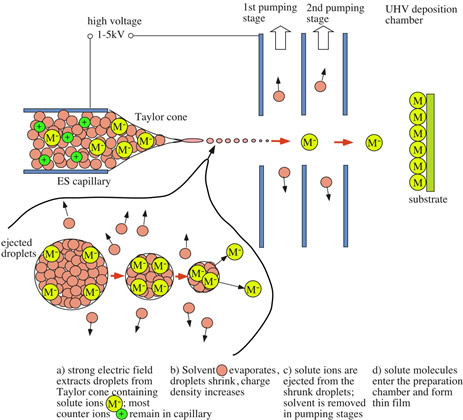

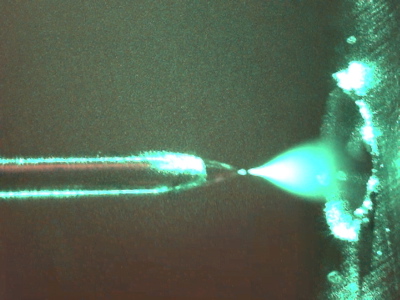

Electrospray Thin Film Deposition of Macro-Molecular Materials in Vacuum: Macro-molecular materials such as polymers or bio-molecules usually cannot be evaporated in vacuum for the preparation of thin films for surface scientific investigation or industrial production processes. This limitation is a result of their high molecular weight in combination with their thermal fragility. To alleviate this constraint, we directly integrated an electrospray injection system (Fig.1) into an ultra high vacuum (UHV) system. Fig.2 shows an actual electrospray as observed at the entrance orifice to the first differential pumping stage. This system allows the direct transfer of macro-molecules from their solution environment into vacuum, where they can be deposited in absence of contaminants. The result are pure thin films that can be used for photoemission spectroscopy experiments or similar UHV based surface scientific techniques. Electrospray thin film deposition allows similar control over the deposition rate like traditional effusion cells, i.e. sub-monolayers can easily be prepared, which enables the investigation of macro-molecular interfaces using photoemission spectroscopy (see electrospray tutorial for more details). Our current research using the electrospray system focuses on the investigation of macro-molecular interfaces (see interfaces research page), on the electrospray deposition process itself, and on design and optimization of the electrospray deposition system. Questions of interest are the charge state of deposited molecules, the thin film morphology, influence of solution pH and other variables on film quality. Another focus is the optimization of the injection efficiency using beam guiding strategies. The application of electrospray for patterning purposes is another focus (see MoleculeWriter page). Some of the technologies for electrospray deposition and patterning in vacuum developed at the Surface Science Lab are now commercially available. Please, visit www.elionsystems.com for more information. |

Fig.1: Electrospray injection process: Solution is injected from capillary onto intake orifice. A high voltage applied between capillary and intake skimmer results in the formation of a Taylor cone, where a separation of positive and negative ions occurs. Droplets containing solvent and mainly ions of bias-matched polarity are emitted towards the intake orifice. En route solvent evaporates, hence charge density increases, resulting in the final ejection of single solute ions, which can be deposited on the substrate. The solvent is removed from the beam through two or more differential pumping stages.

Fig.2: Electrospray plume in front of the entry orifice of the first differential pumping stage. Taylor cone shows up dark at the blunt end of the capillary. Space charge widens the electrospray to a plume. |